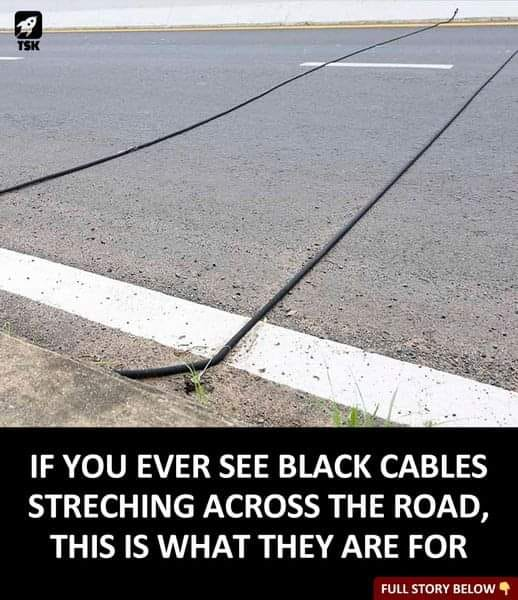

Unveiling the black road cables: Silent traffic observers capturing data for smarter road networks. Data-Driven Traffic Insights

As you navigate the highways and byways of your daily commute, you may have encountered an intriguing sight: black cables stretched across the road, almost like stealthy sentinels of the pavement. But what exactly are these enigmatic tubes, and what role do they play in our transportation infrastructure? The answer lies in the realm of traffic management and data collection.

These unassuming black cables are, in fact, portable traffic counters strategically placed by transportation authorities for research purposes. Primarily used by local agencies, these tubes hold vital insights into road usage and traffic patterns. With more than 12,000 of these traffic counters scattered across the state, they provide invaluable data that fuels the planning and development of our road networks.

Decoding the Mechanism Behind the Black Cables

The technology driving these unobtrusive rubber cords is elegantly simple yet remarkably effective.2 Each time a vehicle’s tires contact the tube, a burst of air is triggered, setting off an electrical signal recorded by a counter device. This ingenious pneumatic mechanism can track the volume of vehicles passing over a road within a given timeframe. Transportation agencies can gain insights into peak traffic congestion periods by analyzing the intervals between these air bursts. When deployed in pairs, these tubes provide even richer data, enabling the determination of vehicle class, speed, and direction.

Such information is far from trivial—it forms the bedrock for informed decisions on road signage, speed limits, and allocation of transportation budgets. Based on these insights, municipalities can fine-tune their traffic management strategies, ensuring that road systems remain efficient and safe for all road users.

Road Tubes: Beyond Just Counting

While the primary function of these pneumatic road tubes is traffic counting, their utility extends far beyond mere enumeration.3 These inconspicuous instruments serve as multi-dimensional data collectors, playing a pivotal role in enhancing our road infrastructure and ensuring smooth traffic flow.

The U.S. Department of Transportation sheds light on the operational intricacies of these tubes. When a vehicle’s tires traverse the rubber tube, a burst of air pressure is generated, closing an air switch that sends an electrical signal to a counter device. These tubes can be set up either as temporary or permanent installations, each serving distinct purposes. Temporary configurations, often lasting only a day, offer quick glimpses into traffic dynamics, while permanent setups provide continuous, in-depth monitoring.

Transportation agencies strategically position these black cables in areas with minimal interference, targeting straight stretches of road for optimal data collection. Through single-tube setups, agencies can gauge vehicle counts and time gaps between vehicles. When utilizing paired tubes, the system delves into the intricacies of traffic, capturing axle count, direction, and speed.

These unassuming tubes also step in when urban road management faces challenges. If residents raise concerns about speeding or shortcutting, these tubes are deployed to investigate and validate claims. The data they generate contributes to the formulation of transportation budgets and the implementation of effective solutions.

In conclusion, the next time you encounter those mysterious black cables stretching across the road, you can appreciate the intricate web of data they weave behind the scenes. These unassuming instruments serve as silent observers, capturing the heartbeat of our roads and guiding the decisions that shape our transportation landscape. As you pass over these tubes, remember that they are more than meets the eye— they are the pulse of our evolving road networks.

Jennifer Lopez Wears a Met Gown That Took 800+ Hours to Make — But People Are Feeling Sad for Her

Jennifer Lopez showcased her unparalleled style at the prestigious 2024 Met Gala. Striding onto the iconic Met steps, she assumed her role as co-chair alongside Zendaya, Chris Hemsworth, and Bad Bunny, exuding her signature glamour and elegance. And while she looked undeniable gorgeous, people were noticing the same thing.

Adhering to the “Garden of Time” dress code, the 54-year-old Lopez stunned in a sheer Schiaparelli Haute Couture gown, adorned with sparkling embellishments resembling butterfly wings.

She complemented her ethereal ensemble with mesmerizing jewels from Tiffany & Co., while elegantly styling her hair in a slightly tousled topknot.

Her gown, a masterpiece of craftsmanship, demanded over 800 hours of meticulous hand embroidery. Crafted with 2,500,000 silver foil bugles and beads, its beauty was not confined to the front; from every angle, including the back, it radiated sheer magnificence.

Online, fans showered praise upon the Maid in Manhattan star for her glamorous appearance and fabulous silhouette. One fan exclaimed, “Gorgeous and stunning as always!” while another noted, “Incredible. She’s an inspiration.”

However, numerous observers couldn’t overlook the fact that the star appeared unhappy, with many noting the absence of her husband, Ben Affleck, from the event. One individual commented, “Looks lovely but unhappy. Trouble in paradise?” while another added, “J. Lo is looking really miserable of late.”

A considerable number of fans were worried and asked, “Where’s Ben?” Additionally, someone pointed out, “Even Matt Damon was there.”

We can definitely agree that Jennifer exuded radiance at this year’s Met Gala. If you’re keen on exploring more stunning looks from the grand event, be sure to check our ranking of the most striking appearances of the night.

Preview photo credit Sipa USA / Alamy Stock Photo, DPRF/STAR MAX/IPx/Associated Press/East News

Leave a Reply