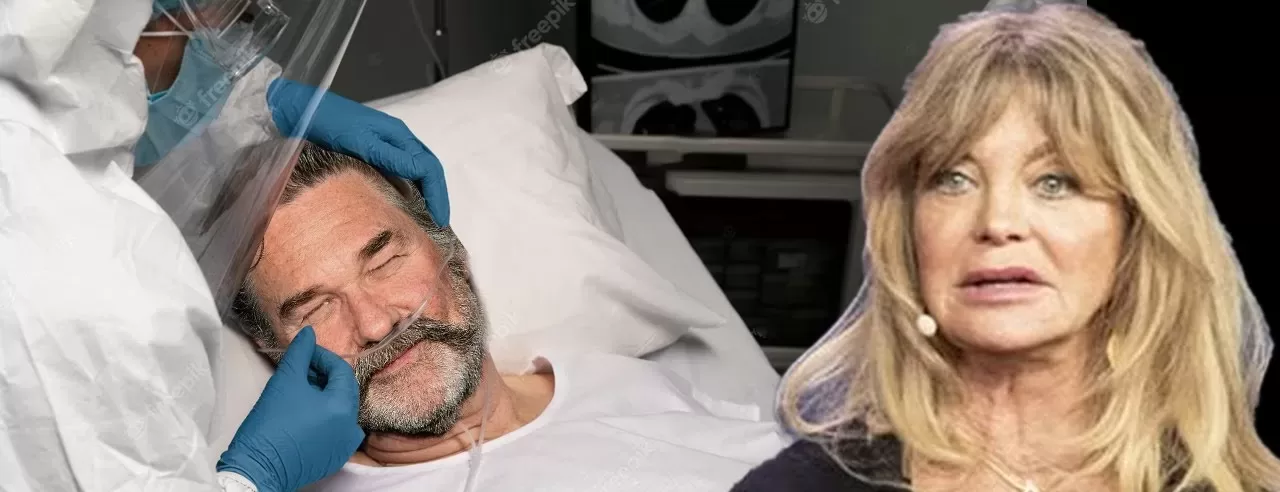

Kurt Vogel Russell is an American actor.At the age of twelve, he made his screen debut in a western series.Russell’s portrayal in Mike Nichol’s Silkwood earned him a nomination for a 1983 Golden Globe for Best Supporting Actor.Massachusetts’ Springfield is where Russell was born.Bing, his father, was an artist as well.His mother is ballerina Louise Julia Russell.Kurt Russell reportedly has a virulent flesh-eating sickness, according to The Globe.The 65-year-old actor from Hateful 8 is said to have had unattractive ulcers under his lower lip, which are a result of Peutz-Jeghers Syndrome (PJS), a condition that has been connected to colon cancer.Cancer.According to Net, “people with PJS may have a lifetime risk of cancer of up to 93%.”Dr. Stuart Fischer, who does not treat Kurt, described the ulcers as “precancerous lesions that can become aggressive and dangerous if not treated immediately and properly.”

Immunologist and Maryland resident Dr. Gabe Mirkin concurs that Kurt “needs immediate testing” and thinks PJS could be the cause of the ulcers.He needs to start counseling right away.We must pray for Kurt Russell. The Globe also claims that Kurt recently got into a fight with Goldie Hawn, his 71-year-old longtime partner.In October, Kurt was supposed to be honored into Oklahoma City’s Hall of Great Western Performers.The Hollywood Walk of Fame already bears his name.Kurt, though, is unable to attend because of a “surprise medical issue.”The actor insisted in a statement that he need surgery, which his doctor stated was a necessary treatment that couldn’t be put off.

The Oklahoman reports that he is scheduled to undergo hip replacement surgery.”My doctors say it needs to happen in September, but I thought it could wait.”As much as I would have hoped to be there this year, I am pleased that the museum has decided to postpone our honor until 2022 so I can accept this wonderful prize in person, Russell stated in the statement.We applaud Kurt Russell on being inducted into the Hall of Great Western Performers!We hope that his treatment later this month goes well and he recovers quickly.

Bottom line: Despite having his name already on the Hollywood Walk of Fame, Kurt ought to be admitted into Oklahoma City’s Hall of Great Western Performers.Kurt, though, is unable to attend because of a “surprise medical issue.”The actor, 64, was spotted in New Orleans sporting cuts and bruises on his face and arms.Kurt Russell has a fatal flesh-eating sickness, according to The Globe.

Gisele Bündchen’s New Love Revealed – You Won’t Believe Who!

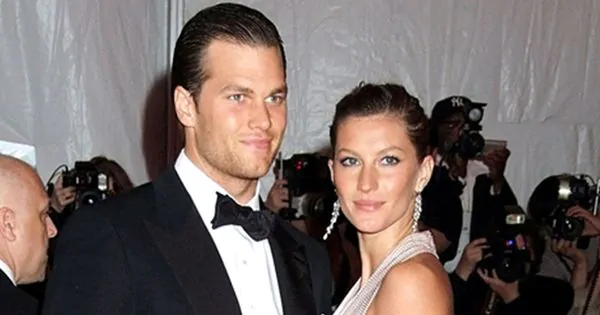

Gisele Bündchen and Tom Brady, a famous couple loved by many, recently decided to go their separate ways, which left their fans feeling sad. However, both Gisele and Tom seem ready to move on. So, who is the man who has captured Gisele’s heart now? Let’s find out!

After being married for 13 years and raising two children together, NFL star Tom Brady and supermodel Gisele Bündchen decided to split up in 2022. They started dating in January 2007 and got married on February 26, 2009. They have two children together – 14-year-old Benjamin and 11-year-old Vivian. Tom Brady also has a 16-year-old son named Jack from a previous relationship.

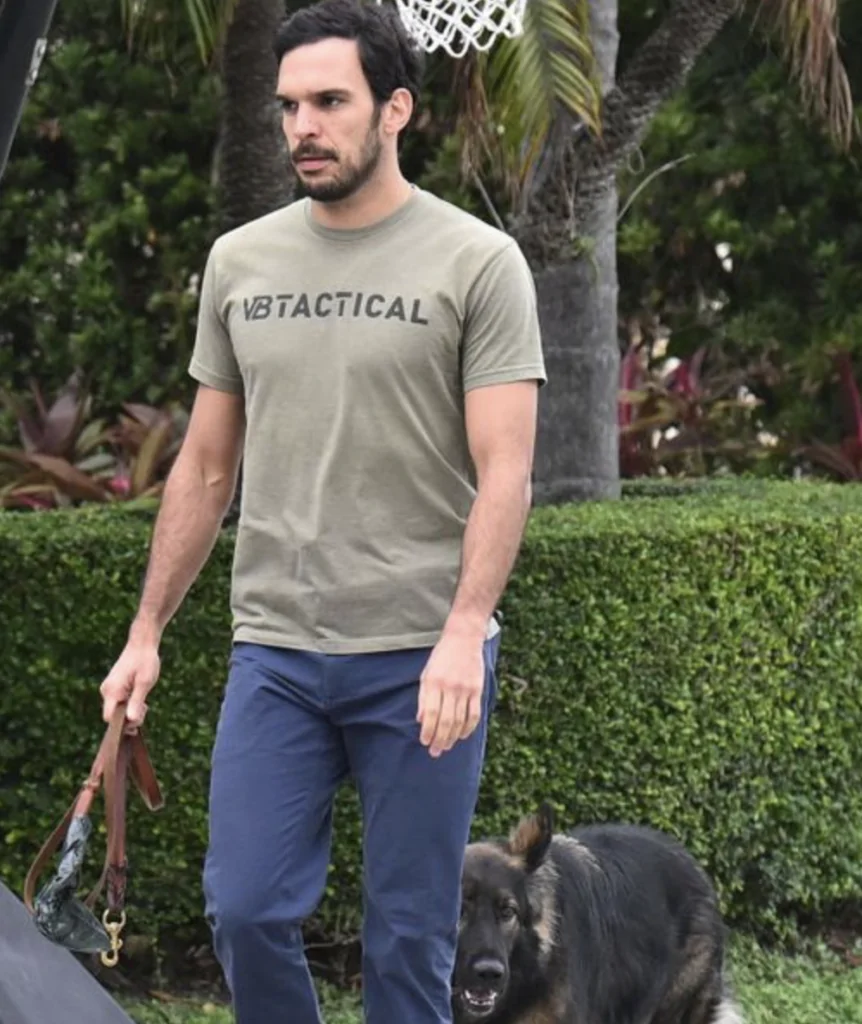

There are rumors that Gisele is now dating Joaquim Valente, a jiu-jitsu instructor who was originally just a friend. But their relationship quickly grew into something more. Sources say Gisele and Joaquim have been romantically involved.

Joaquim Valente has been a source of support for Gisele during this new phase of her life after her divorce. What makes their relationship special is that they were close friends before becoming romantically involved. “He has been there for her as she moves forward in this new phase of life after her divorce, and it has been a positive change for her,” a source revealed.

Gisele and Valente share many interests, especially their passion for wellness. Their shared love for staying active, traveling, and taking care of their health has strengthened their bond. “They connect deeply and have a lot of fun together,” the source added.

While Gisele hasn’t directly confirmed the romantic rumors, she has talked about how important Valente is in her life. In an interview with People magazine in March 2023, Gisele expressed gratitude for Valente, highlighting his role as a martial arts instructor for her and her children.

In May of the same year, Gisele and Valente were seen enjoying time together on a beach in Miami. They looked genuinely happy and enjoyed each other’s company.

If you found this story interesting, make sure to check out another article where Gisele explains the real reason behind her divorce from Tom Brady.

Leave a Reply