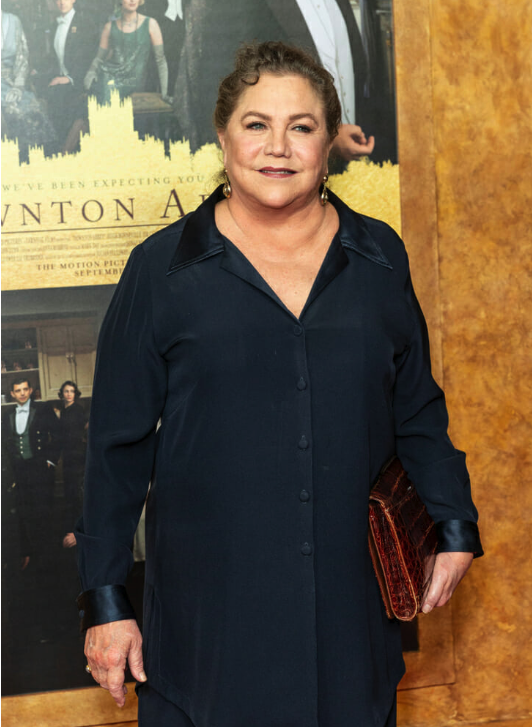

Kathleen Turner rose to fame in the 1980s as a result of her strength and beauty; many consider her to be one of Hollywood’s most beautiful actors.

Over the years, the actress has faced numerous challenging and favorable situations, and her perseverance has carried her through them both.Kathleen Turner was raised in a home with four other children, despite her difficult past.

She and her siblings were raised in both Venezuela and London. When she was a little girl, she tragically witnessed her father’s sudden death when he was mowing the lawn of their Hampstead house.

A month following his passing, the foreign service ejected Kathleen and her family from the United Kingdom. In Springfield, Missouri, where everyone was still grieving for their father and their previous home, Turner relocated her family.

Finally, Tuner felt at peace after moving to New York to pursue an adult acting career. Her major break came when she was hired as the femme fatale in the 1981 film “Body Heat,” despite her success on stage.

Turner was offered the opportunity to co-star with Michael Douglas in the well-known “Romancing the Stone” three years after sharing the screen with William Hurt. During filming, Douglas was going through a difficult divorce from his wife Diandra, and he started to feel a connection with Turner.

We were intensely flirting and exchanging intense, yearning glances as we were falling in love. Kathleen remarked, “Then Diandra came down and reminded me he was still married.”

In the end, she wed Jay Weiss, the movie’s real estate developer, in 1984. Soon after, the couple welcomed their only daughter together. October 14, 1987, was Rachel Ann Weiss’s birthday.

Regretfully, when the couple started parenting their daughter, their relationship started to fall apart.

“I would demand extended weekends or additional passes from the film studios so that my spouse and daughter could visit me. However, I felt bad since there was a feeling in the marriage that all the work was on his end. It terminated for a few reasons, including that. I began to experience extreme oppression. Kathleen said, “I thought, ‘Hang on a minute, you’ve done very well out of being married to me also.’”

When Turner played Martha in the 2005 Broadway production of “Who’s Afraid of Virginia Woolf?” their marital problems came to a head. Turner became incredibly busy performing in eight shows a week, and it seemed Weiss didn’t want to spend any time with her at home.

During that time, Turner was nominated for a Tony Award for her portrayal of Martha, and the two got along well.

The actress was nominated for an Oscar in 1987 for her role in “Peggy Sue Got Married.” She went on to produce several films in the 1980s, including three blockbusters starring Michael Douglas.

But in the 1990s, Kathleen experienced a medical setback when her neck locked, making it impossible for her to turn her head. Additionally, the swelling in her hands prevented her from using them.

Kathleen stated, “It was crippling.” When something is gone, even for a little while, you stop taking it for granted. What I took for granted was my athleticism, my capacity for forceful movement, and my freedom to move however I pleased. I had a genuine identity crisis when I lost that: “Who am I if I can’t do this?”

She was diagnosed with rheumatoid arthritis, which is characterized by swelling of the lining of our joints, and this was the tragic reason for her circumstances. Managing chronic pain caused by this illness can be difficult.

Kathleen remarked, “When it was first diagnosed, I was terrified because they said I’d be in a wheelchair.” “I reasoned that I couldn’t act if I couldn’t move. Not everything I want to do is act. I was destined for this. It’s present throughout my entire life. The most terrifying aspect was the thought of not being able to accomplish it, together with the ongoing discomfort.

Kathleen took drugs and alcohol to ease her pain. Her habit of drinking vodka led her to faint during dress rehearsals for plays such as the 2002 stage version of “The Graduate,” even if they made her job simpler.

The actress really checked herself into rehab after the show concluded, and it was found that she was not an alcoholic. Instead, she was told to just remember to take more notes on when she took her medications and any unfavorable side effects.

The actress now does pilates and yoga to help her stay flexible and manage her discomfort.

The famous person began to focus more intently on her career in theater while also improving her pain management. As she grew older, she largely returned to her roots, even taking the lead in a stage production of “Cat on a Hot Tin Roof” in her forties, even though she still worked sometimes in film and television.

“It was a little foresight on my part of which I am justly proud, because I knew that the better roles as I got older would be in theatre, which is absolutely true,” Kathleen remarked.

By focusing on the theater, the actress has had more time to pursue her passions, which include working for Planned Parenthood of America and volunteering for Amnesty International.

For most of her life, Turner has been an ardent feminist who has devoted her life to helping other women. Gloria Feldt’s 2008 biography of the actress, Send Yourself Roses, captures her thoughts perfectly.

As women, we are the first generation to achieve financial independence. Women are returning to the workforce, stated Kathleen. They’re redefining who they are. I believed I could contribute to that, even more. It therefore contains a great deal of philosophy as well as my personal beliefs.

What are your thoughts on Kathleen Turner’s difficult yet fruitful journey? Tell us in the comments below!

Why I Never Make My Son Say ‘Thank You’ or ‘Sorry’ Anymore

Parenting is no easy task. We all have our unique styles, and let’s face it, there’s no shortage of opinions – wanted or otherwise. But for Emma, a proud member of the ‘understanding and empathic’ tribe, breaking the mold of traditional parenting has been a life-changing decision.

Introducing Emma, a caring and open-minded mother, who has turned to the internet to discuss her controversial parenting choices and seek advice from the masses. In a heartfelt letter, she shares her story and hopes to hear what other parents think about her son’s situation.

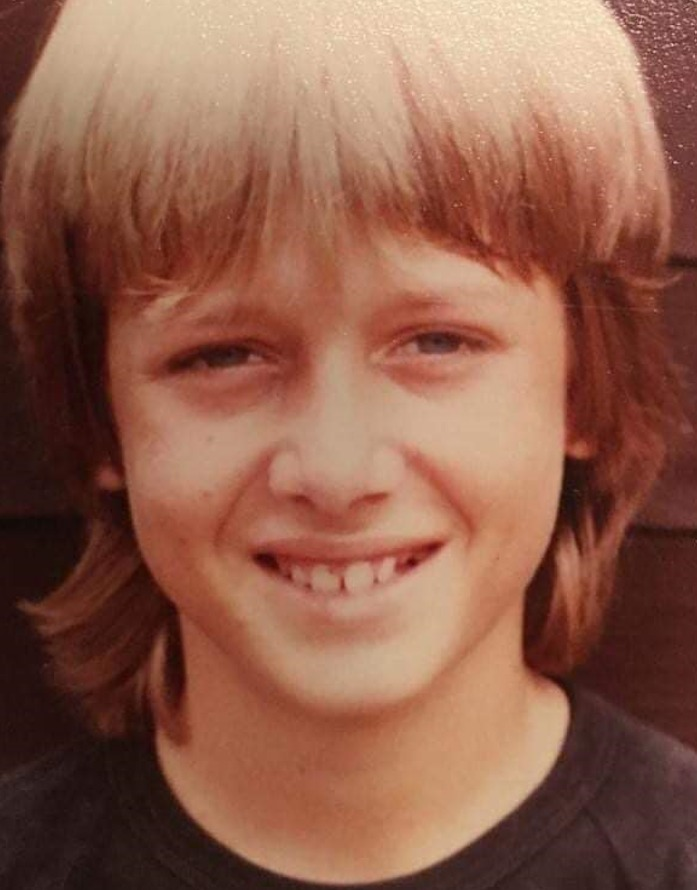

At 38 years old, Emma is the adoring mother of eight-year-old Georgie. Georgie is her pride and joy, and Emma has made it her mission to raise him differently from the norm. She believes in embracing a parenting approach that goes beyond discipline and focuses on understanding and empathy.

Emma’s approach is unconventional, and that’s what makes it stand out. She recognizes the power of platforms like ours, where people can freely express their opinions on different topics. In the past, Emma has actively engaged with others by offering suggestions and sharing her interpretations of their stories. Now, she invites readers to share their thoughts on her son’s unique situation.

Georgie’s upbringing has been shaped by Emma’s unwavering commitment to compassion and understanding. Through this different approach, she hopes to create an environment where Georgie can thrive, feel heard, and grow into the best version of himself.

Join us as we delve into Emma and Georgie’s journey, discovering the joys and challenges of breaking the parenting mold. Let’s explore the power of empathy, compassion, and unconventional choices in raising happy and confident children.

Leave a Reply