Imagine dreaming of an expandable container home that can travel with you, unfolding into a comfortable living space quickly, and equipped with all the essentials.

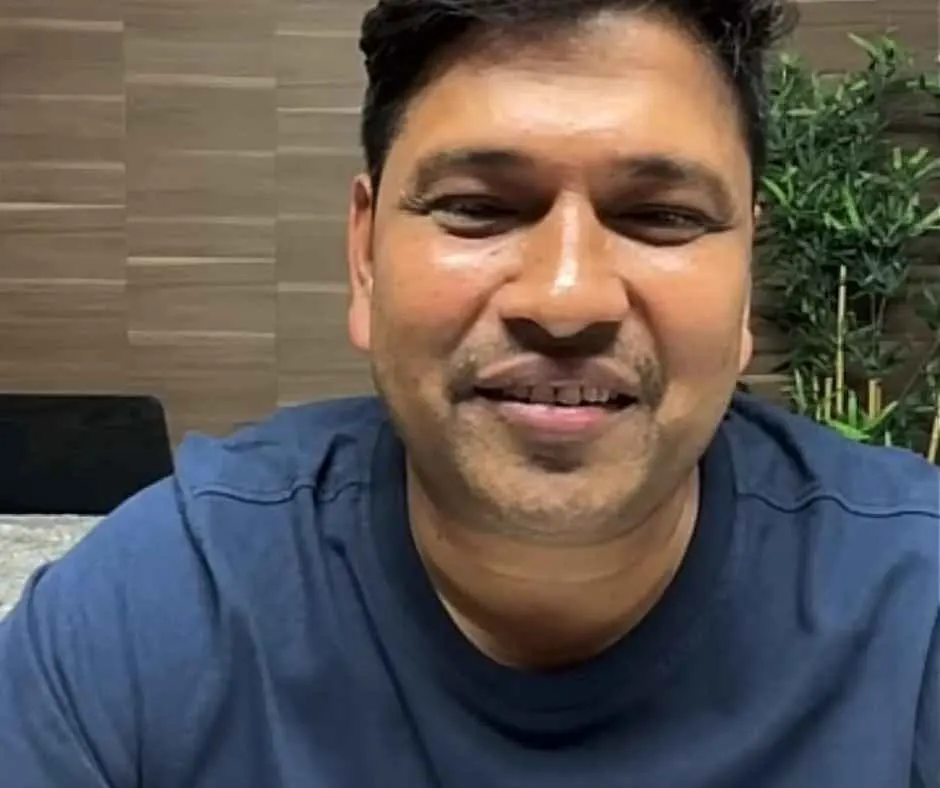

That’s exactly what Kamal Kadhar dreamed of ten years ago, inspired by innovative designs he discovered online.

Despite lacking formal construction training, Kamal started a journey fueled by determination and passion.

Using his earnings from eight years of driving for Uber, Kamal built a compact yet expandable container home measuring 7.5 feet by 24 feet.

The beauty of his creation lies in its portability – it can be towed by a 4×4 vehicle, eliminating the need for cranes or forklifts.

Kamal’s journey began in a field outside Tiruchirappalli, a southern Indian city, where he constructed his first prototype.

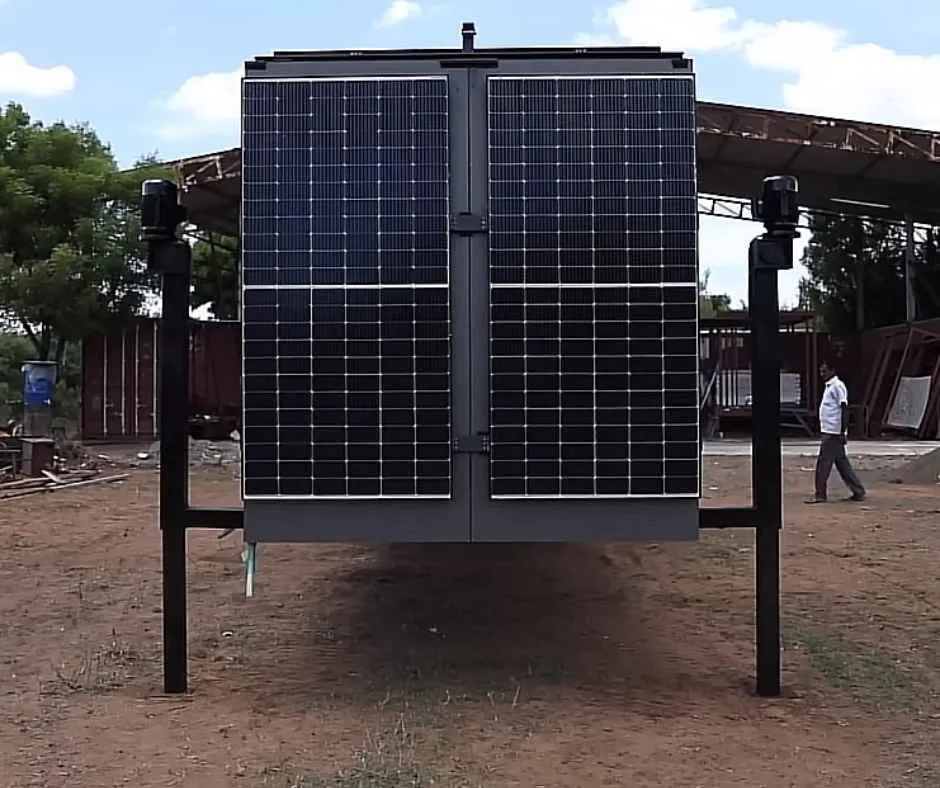

What sets Kamal’s creation apart is its simplicity and resilience. He opted for mechanical winches instead of complex hydraulics to ensure ease of deployment in remote locations.

As Kamal describes it, the expandable container home is like an octopus – small when needed, expandable when necessary, and can withstand disasters like fires, hurricanes, or floods.

The relocation process is as easy as moving a shipping container, making it legally transportable anywhere in the world using a 4×4 SUV.

The journey wasn’t without its challenges.

After investing almost a decade of hard work and facing financial strain, Kamal’s family was on the verge of giving up.

However, witnessing the prototype changed everything. Realizing the idea’s value brought relief despite the personal and financial sacrifices.

Kamal’s unconventional path involved learning everything from YouTube, combining his experiences as an Uber driver with visits to construction sites and apprenticeships at a builder’s shop.

The relocation process is as easy as moving a shipping container, making it legally transportable anywhere in the world using a 4×4 SUV.

The journey wasn’t without its challenges.

After investing almost a decade of hard work and facing financial strain, Kamal’s family was on the verge of giving up.

However, witnessing the prototype changed everything. Realizing the idea’s value brought relief despite the personal and financial sacrifices.

Kamal’s unconventional path involved learning everything from YouTube, combining his experiences as an Uber driver with visits to construction sites and apprenticeships at a builder’s shop.

His creative mindset was founded on his father’s small scrap metal shop, where he played with metal and aluminum, shaping the project to resemble a regular shipping container.

The main structure starts small at 7ft 6in and expands to 20ft.

The expandable container home takes less than 2 hours to build, with a foundation not required.

It can be adjusted on uneven surfaces using built-in leg jacks.

The roof opens with stainless steel hinges, both mechanical and electrical components, avoiding hydraulics for reliability.

The roof opens to add solar panels, maximizing power generation for personal use or resale to the government by connecting to the grid.

The sides expand mechanically, controlled by a hinge, making it easy to pull and open with just one finger.

The kitchen, also expandable, is attached to the bathroom facility. Utilities run down the middle, and it’s designed to hook up to city sewage.

The living area is spacious, with a total interior size of 300 square feet, and the bedroom features a foldable bed.

This house has been tested in a remote village, and even non-professionals helped build it confidently.

You can expand it and adjust the interior to make it more spacious.

My Sassy Stepmom and Her 4 Adult Kids Wore All White to My Dad’s Funeral – Everyone Gasped When She Took Out a Letter

I expected my father’s funeral to be a day of quiet mourning, a time to honor the man who had held our family together. What I didn’t expect was my stepmom turning it into her personal drama — until a letter from my dad revealed secrets that left her and her kids humiliated in front of everyone.

The day of my dad’s funeral was already one of the hardest days of my life. I’d barely managed to keep myself from breaking down that morning, knowing I was about to say goodbye to the man who had held our family together.

Emotional woman at her dad’s funeral | Source: Midjourney

He’d been sick for a long time, and while we all saw this day coming, nothing prepared me for the suffocating weight of it when it finally arrived.

And then they showed up.

Vivian, my stepmom, waltzed in like she was on a runway, her four adult kids trailing behind her, all dressed in white. Stark, glaring white — like they’d gotten lost on the way to a fancy yacht party.

Everyone else was draped in black, heads bowed, grieving. But not them. No, they strutted in like they were attending some exclusive event, turning heads for all the wrong reasons.

Senior woman and her children wearing white at a funeral | Source: Midjourney

I couldn’t believe what I was seeing. My chest tightened with anger as I pushed through the crowd and made a beeline for her.

“Vivian,” I snapped, my voice low but sharp enough to cut through the soft murmurs around us, “what the hell are you doing? Why are you dressed like—” I gestured wildly at her flowing white dress and her kids’ matching outfits, “—like this at my dad’s funeral?”

She didn’t even flinch. Instead, she gave me this lazy, condescending smile that only made my blood boil more.

Senior woman and young lady talking at a funeral | Source: Midjourney

“Oh, sweetheart,” she said, dragging out the words like I was a child throwing a tantrum. “Don’t get all worked up. Your father wanted this.”

“Wanted this?” I repeated, my voice rising despite my best efforts to stay calm. “There’s no way Dad would’ve—”

She cut me off, reaching into her designer handbag and pulling out a neatly folded envelope. “He wrote me a letter,” she said, holding it out as if it explained everything. “Told me, ‘Vivian, you and the kids are to wear white. It’s my last wish.’”

Senior woman holding an envelope | Source: Midjourney

I stared at the letter in her hand, feeling the eyes of everyone around us. Whispers were already starting to spread through the crowd.

“No,” I said, shaking my head. “There’s no way he—”

“He did, darling,” she interrupted with a sigh, her eyes gleaming as though she was enjoying the scene. “He told me it was going to be something special. You should be grateful we’re honoring his wishes.”

I could hear people gasping behind me, the tension in the room rising with every passing second.

“Are you serious?” I demanded, my voice trembling now. “You really expect me to believe Dad wanted this — to turn his funeral into some… spectacle?”

Senior woman and young lady talking at a funeral | Source: Midjourney

Vivian shrugged, tucking the letter back into her bag. “Believe whatever you want,” she said coolly, “but we’re just following his final instructions. It’s what he wanted.”

I could feel my hands shaking, the rage bubbling up inside me, but before I could say another word, she turned to her kids and said, “Come on, let’s go take our seats. We don’t want to be late.”

I stood there, speechless, as they sauntered toward the front row, leaving me to simmer in a storm of confusion and fury.

Sad young lady at a funeral | Source: Midjourney

The ceremony began, and sure enough, she and her kids took their place in the front row, dressed like they were VIPs at some fancy gala. They soaked in the attention, their white clothes practically glowing against the backdrop of mourners in black.

Just when I thought I couldn’t handle their arrogance anymore, Joe, my dad’s best friend, stepped up to the front. His face was tight with emotion, eyes heavy with grief, but there was something else there too — a tension that made my stomach twist.

Senior man giving a speech at a funeral | Source: Midjourney

He cleared his throat, the room going completely silent as everyone turned their gaze toward him. In his hand, he held a letter.

“Vivian,” he said, his voice firm but calm. He gestured for her to stand, and I could see the tiniest hint of a smirk play on her lips. She rose slowly, her chin lifted like she was about to accept an award. Her kids followed, standing beside her with smug looks of their own.

“This letter…” Joe began, his voice wavering just slightly, “was written by your husband.”

Joe’s voice was steady as he began to read from the letter, and the entire room seemed to hold its breath.

Senior man reading a letter at a funeral | Source: Midjourney

“To my dearest friends and family,” Joe read, his voice thick with emotion. “I want to thank you all for being here today, for honoring my memory. There’s something I need to address, something that’s been weighing on my heart.”

I glanced at Vivian. Her expression, once smug and superior, began to shift. A flicker of unease crept into her eyes as she straightened, her gaze darting nervously around the room.

Senior woman wearing a white dress at a funeral | Source: Midjourney

Joe continued, “I couldn’t help but notice that during my illness, my ex-wife, Martha, was the one who took care of me. She was there when I needed someone the most, while Vivian and her kids were always absent — unless, of course, they needed something from me.”

Vivian’s face drained of color. She stood rigidly, frozen as if willing herself to disappear.

Her kids, who had been sitting confidently, were now nervous, their eyes wide with fear.

Young adults wearing white at a funeral | Source: Midjourney

Murmurs rippled through the crowd like a wave, and I could see people exchanging shocked glances.

“That’s not true!” Vivian suddenly hissed under her breath, but her voice cracked, betraying her fear.

Joe barely paused. “It became clear to me that my new family was more interested in what I could provide than in who I was. And then,” he glanced pointedly at Vivian, “I found out, through my financial adviser, that money had been disappearing from my accounts. We investigated and discovered that Vivian and her children were behind it.”

Senior man reading a letter at a funeral | Source: Midjourney

A collective gasp filled the room. It felt like the walls themselves shuddered with the sound. Vivian’s kids, who had been sitting so confidently, now looked as pale as ghosts, as the eyes of every guest bore down on them.

Vivian’s face contorted in anger, her mask of calm shattering completely. “This is a lie!” she yelled, her voice trembling with fury. “A complete fabrication! You can’t believe this garbage!”

Her hands clenched into fists as she looked wildly around the room as if searching for someone to step in and defend her.

But no one spoke. The silence was deafening.

Joe’s gaze didn’t waver. He raised the letter again and continued, his voice unwavering.

Senior man reading a letter at a funeral | Source: Midjourney

“I knew they would come to my funeral, expecting to play the role of the grieving family. So, I asked them to wear white. I wanted them to stand out, so everyone could see them for what they are.”

Vivian gasped, her eyes wide with disbelief. “You bastard,” she spat, her voice shaking with venomous rage. “You think you can humiliate me in front of everyone like this? You’ll regret this! You all will!”

But Joe didn’t stop. His voice rang out loud and clear, cutting through her rage like a blade. “Vivian, you and your children are no longer welcome here. This is a place for those who loved me for who I was, not for what I could give them. Please leave, and let my true family and friends mourn in peace.”

Senior man reading a letter at a funeral | Source: Midjourney

The silence was suffocating. Every eye in the room was fixed on Vivian and her kids, waiting for their next move. Her face was a chaotic swirl of emotions — shock, rage, humiliation. For a split second, it seemed like she might explode, her eyes wild with fury.

But then, she glanced around and saw the faces of the guests — cold, unforgiving glares. The weight of judgment pressed down on her, and whatever fight she had left in her fizzled out.

Crowd at a funeral | Source: Midjourney

Her kids, once so full of smug confidence, shrank under the scrutiny, their eyes fixed on the floor as if they could disappear into it.

Vivian huffed loudly, her lips curling in disgust. “Fine! This whole thing is a farce anyway,” she spat, yanking her purse from the chair. Her voice dripped with venom, but everyone could see she was cornered. Defeated. “Come on,” she snapped at her kids, her voice sharp as broken glass.

Vivian stormed toward the exit, her heels clicking against the floor with a fury that couldn’t hide her humiliation.

She was finished, and she knew it.

Senior woman walking out of a funeral | Source: Midjourney

The door slammed shut behind them, leaving a thick silence in their wake. No one moved for a long moment, as if the room was exhaling after the storm.

Joe calmly folded the letter, his eyes scanning the room with a somber expression. “Now,” he said, his voice steady, “let’s continue with remembering the man who truly deserves to be honored today.”

Senior man giving a speech at a funeral | Source: Midjourney

And so we did. The ceremony went on peacefully, a celebration of my dad’s life surrounded by the people who had loved him for who he was. We laughed, we cried, and we shared stories that captured the essence of the man who had brought us all together.

As for Vivian? She got exactly what she deserved — an exit cloaked in shame and disgrace. My dad, even in death, had the last laugh. He had exposed them, stripped away their pretenses, and made sure the truth came out in the end.

Close-up shot of a casket | Source: Midjourney

My dad may have been gone, but his wisdom — his sense of justice — was alive and well. And as I listened to Joe recount a funny story about my dad, one thing was clear.

“Dad always knew how to pick his moments,” I whispered.

Younng lady at her father’s funeral | Source: Midjourney

Leave a Reply